We use our 40 years of experience, knowledge and know-how to design and manufacture our market-leading electrostatic precipitators, providing you with the most effective kitchen extract filtration products available.

Here are the real 5 top truths about ESP air filtration in the UK market and what you need to know to help you choose the best product for your next project:

Truth 1: Treatable Air Volume

Regarding the volume an ESP can handle we need to analyse what we want to filter. The primary use for ESP’s in the cooking extract market is to remove sub-micron particles of smoke and grease. Any engineer will know that you cannot alter basic physics, one of the primary factors in an ESP is the size of the collector cell. The changeable factors are the charging voltage, the gap between the plates and the length of travel through the collector. Some suppliers may claim to handle very high volumes of air, these claims are disingenuous and deceiving. In theory an ESP can deal with any size airflow and filter particulates from the airstream. As our Sales Director explains:

“We could advertise that, for example, a three-cell ESP 4500E could deal with up to 4m3/s at 95% efficiency, which sounds very impressive. However, if you were to look in closer detail, it would most likely show 95% efficiency of large particles above 10 microns (for scale, the average size of human hair is 70 microns) these are not the particles you need to worry about. It is the smaller sub-micron particles that need to be captured and those will just pass through an incorrectly sized unit.

The same can be said when suppliers quote that testing is based on ASHRAE 52.2, which sounds impressive; however, it actually means very little without a detailed report. ASHRAE 52.2 covers testing particles from 0.3 microns all the way to 10 microns in diameter, providing 95%+ efficiency for the larger particles is most certainly standard for any ESP. Despite the fact that our ESP 4500E can filter particles way beyond an air volume of 3m3/s, we suggest a recommended maximum volume of 2.1 m3/s, and we make this recommendation because our focus is on the sub-micron particles (grease vapour and smoke) that we need to capture in a successful installation.”

Andrew James

Sales Director, Purified Air

Truth 2: High efficiency is vital

The purpose of ESPs in kitchen extract systems is to filter the smallest of particles at very high efficiency. If extract air is run through an ESP at too high a velocity, the probability of capture will reduce, resulting in unacceptable smoke and grease breakthrough and problems for the operator and installer.

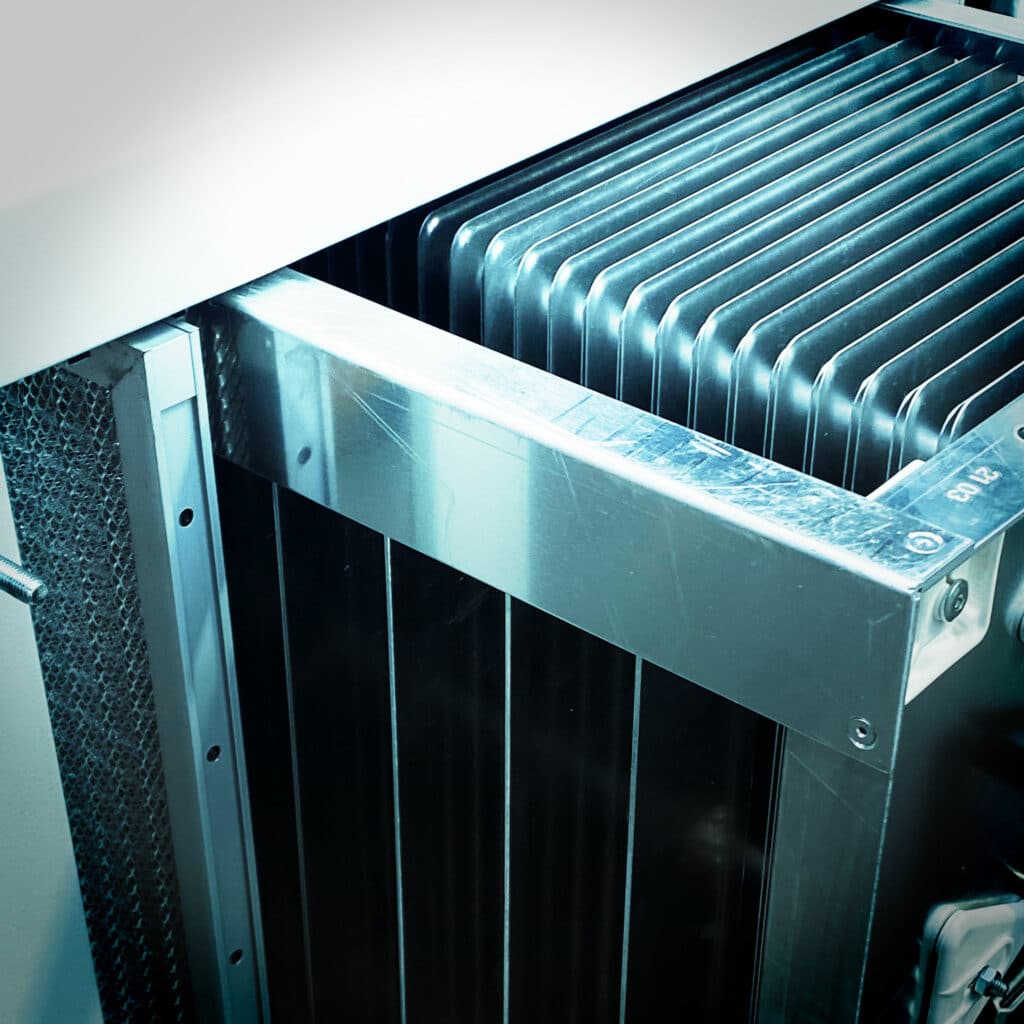

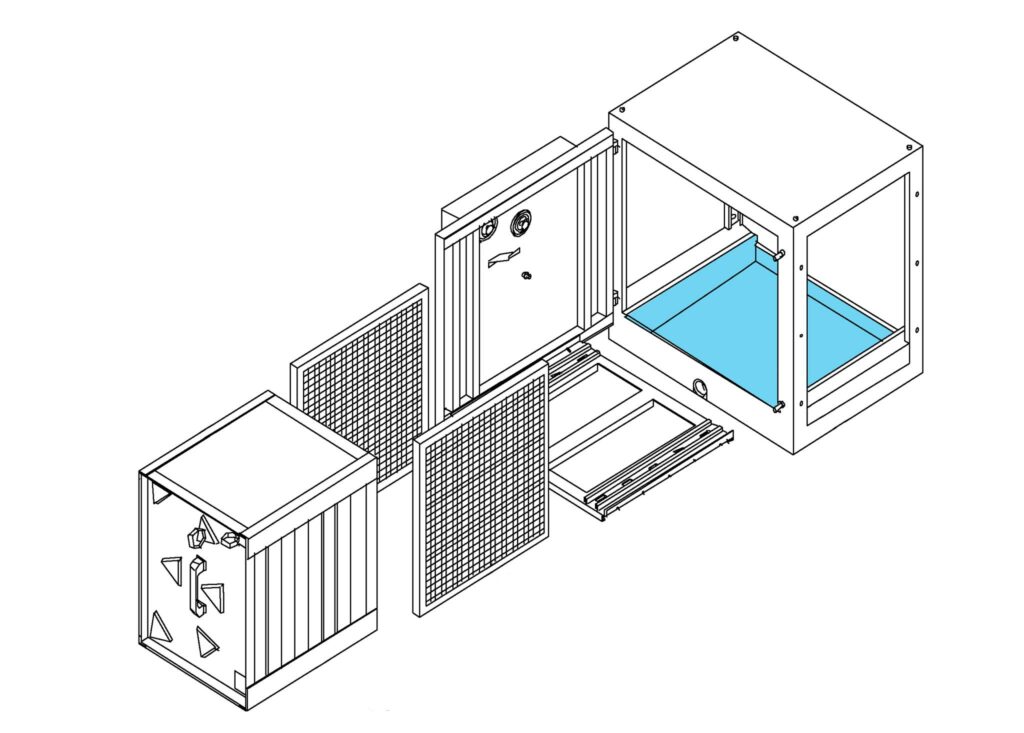

Truth 3: Bigger sumps are better

It’s not only the performance that defines an effective ESP; it’s the ability to collect and hold the contaminants that we are filtering until service is carried out. A large sump (separated from the airflow) helps to collect the oil and grease that drips from the plates which would otherwise line the ductwork and become a fire hazard. A kitchen exhaust is a highly polluted environment where it is essential to be able to hold the captured contaminant to avoid increased service frequencies or leakage outside of the unit. It is also important to distinguish the difference between an integrated sump and a ‘drain sump option’ this terminology is often used for products that are designed for welding fume applications and can often only hold a small amount of captured oil. After extensive evaluation, we designed our unit to hold 16 litres per collector cell which is between three and five times more than our competitors.

Truth 4: We are the only UK company with an IP65 rated ESP

The IP65 rating means our ESP’s are able to be installed outside. To break it down, the 6 means that the unit is dust tight, and the 5 means that the unit is resistant to high-power water jets from all directions. Units with a lesser rating are limited in their ability to be installed outside. E.g. A claim of IPX4 means that no test has been made for dust ingress, and the unit is only rated 4 for water ingress.

Truth 5: We are the only manufacturer of commercial kitchen ESPs in the UK

We are the only UK company that design and manufacture ESPs specifically to meet the demands of commercial kitchen air filtration. Our ESP range are not intended or used for any other purpose. Other suppliers in the UK purchase their equipment from manufacturers abroad, and these units are normally designed for industrial purposes rather than that of the commercial kitchen environment.

Why choose Purified Air ESPs?

UK Manufacturer

In the UK, we are the only manufacturer to engineer & design their product.

Since 1984

We have a wealth of experience in kitchen air filtration.

No lead times

Built for stock ,not to order.

Direct Servicing

We directly employ our service and maintenance teams. We do not subcontract or use other companies to complete our servicing contracts.