UV-O Range

Commercial Kitchen Filtration

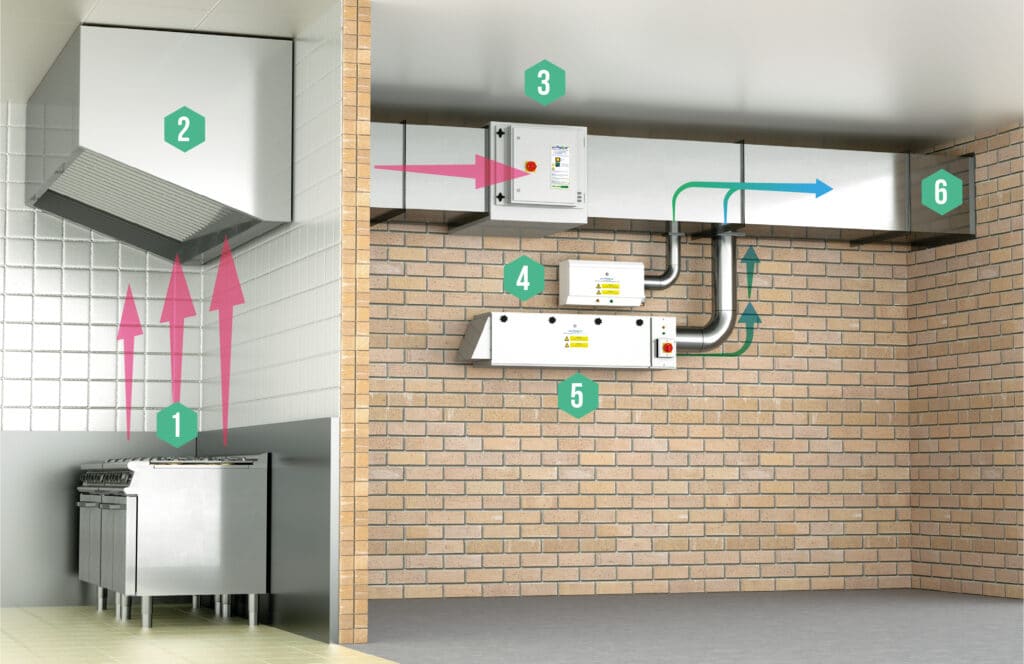

Unlike other UV-C systems, our UV-O units are located outside of the kitchen extract duct and are connected via a spigot and spiral ducting.

The UV-O 500 has been designed for smaller capacity commercial kitchens. The UV-O range uses UV-C technology to produce ozone and hydroxyl free radicals to oxidise cooking odours through a process of ozonolysis. Unlike other UV-C systems, our UV-O units are located outside of the kitchen extract duct and are connected via a spigot and small diameter ducting.

Established

reliable technology

Easily retro-fit

to existing system

Highly efficient

Competitive Cost

/ High availability

TRIED & Tested

This unit’s tried and tested UV-C technology ensures high levels of odour reduction prior to discharge which makes siting commercial kitchens in residential areas more viable. After extensive research and development Purified Air are able to devise the best combination of lamps at different wave lengths, which when combined with the photo catalytic liner provides the most effective odour control.

The benefits of UV-O technology

Eliminates up to 90% of odours

Easy to retro-fit

Low maintenance

Low pressure loss

UV-O 500

Max air volume

up to 1.5m3/sec

Dimensions

W610mm | H300mm | D200mm

Weight

10.5KG (Approx)

Power

140W

UV-O 1000

Max air volume

up to 2.5m3/sec

Dimensions

W1521mm | H350mm | D404mm

Weight

50KG (Approx)

Power

640W

UV-O 500

Max air volume

up to 3178 cfm

Dimensions

W 24 in | H 11.8 in | D 7.9 in

Weight

24 lb (Approx)

Power

140W

UV-O 1000

Max air volume

up to 5297 cfm

Dimensions

W 59.9 in | H 13.8 in | D 15.9

Weight

111 lb (Approx)

Power

640W

Please note: This equipment needs to be interlocked with the extract fan.

How it works

When installed correctly our UV-O systems can reduce cooking odours by up to 90%. For optimum performance we would recommend between 2 & 6 seconds of dwell time.

- Cooking particulates

and odours - Canopy Grease Filter

- ESP – Particulate

Control Unit - UV-500

- UV-O 1000

- Ozone breaks down odours within the duct

Technology

used by

Our commercial air filtration systems have been installed in the kitchens of some of the world’s most prestigious brands.